Wuxi Xingsheng New Material Technology Co.,Ltd.

Tel:0086-510-87871828 510-87816719

Fax:0086-510-87816866

NETWORK:www.yx-xd.com

MAIL:jsxd828@vip.163.com

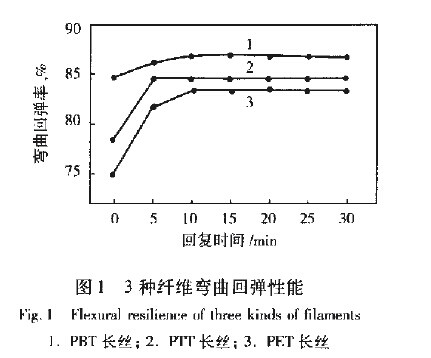

Under the same conditions, the bending resilience of PBT, PTT, and PET fibers are measured, the results are shown in Figure I. From the Figure I, PBT fiber has the highest flexural resilience, followed by PTT fiber, PET fiber is the lowest. The flexural resilience of all three fibers increases with the extension of recovery time. When the recovery time is 0, the difference in the bending resilience of the three fibers is the largest, and decreases as the recovery time increases. It can also be seen from Figure 1, as the high bending resilience of PBT fiber, the recovery time has little impact on the bending resilience, only 2.7% change from the instant of rebound to equilibrium, while the impact of PT and PET fiber recovery time on their bending resilience is significantly increased, with 7.8% and 11% change from the instant of rebound to equilibrium respectively. In addition, when the recovery time reaches more than 10 minutes, the bending resilience of the three fibers reach a balanced value, therefore the recovery time can be set to 10 minutes to meet the test requirements.

Correlation between fiber resilience and mechanical properties

From Table 1, it shows that among the three fibers, PTT fiber has the lowest Young's modulus, PBT fiber has a slightly higher one, and PET fiber is the highest, indicating that Prr fiber has the worst rigidity. The breakingratio of PTT fibers is between PET and PBT fibers, indicating that the toughness of PTT fibers is higher than that of PBT fibers, but lower than that of PET fibers. Thanks to the lowest breaking strength and highest elongation at break of PTT fibers, its high toughness is mainly due to the contribution of higher elongation at break.

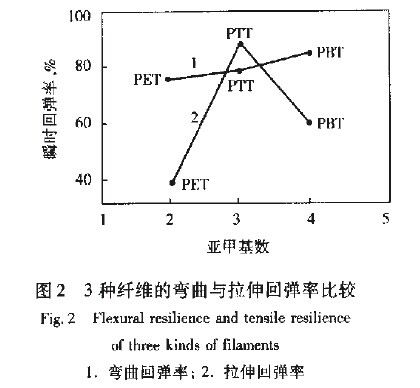

From table 2, there is no significant correlation between the instantaneous bending resilience and the instantaneous tensile resilience of the three fibers. In terms of tensile resilience, PTT fiber is the highest, followed by PBT fiber, and PET fiber is the lowest; The bending resilience of PBT fiber is the highest, followed by PTT fiber, and PET fiber is the lowest. The lack of correlation between bending and tensile rebound rates is due to the fact that these two rebound rates are measured under different elongation conditions.

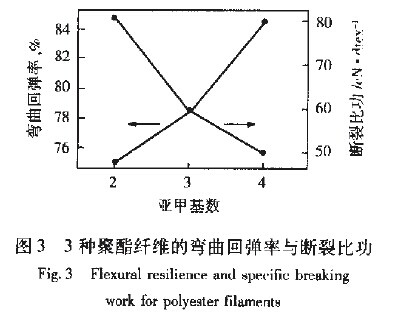

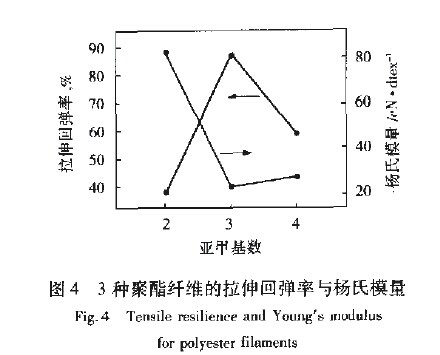

From table 3 and table 4, it shows that there is a significant correlation between the fiber bending resilience and its fracture ratio, as well as between the tensile resilience and Young's modulus. With the increase of the methylene base number, the flexural resilience of the fiber increases, while the specific work at break decreases. This indicates that the increase of the methylene base number reduces the rigidity of the macromolecular chain and the ability of the fiber molecules to resist deformation, resulting in improved and increased flexural resilience. In addition, there is also an inverse relationship between the tensile resilience of fibers and their Young's modulus, which reaches an extreme value at three methylene points. That is, with the increase of the methylene number, the tensile resilience of fibers firstly increases, and then decreases with the increase of the methylene number, while the Young's modulus first decreases with the increase of the methylene number, and then slightly increases with the increase of the methylene number.

Bending elastic recovery mechanism of aromatic poly (vinyl acetate) fibers the characteristic of fiber bending elastic recovery is recovery at lower elongation. The macromolecular chain structures of PET, PTT, and PBT fibers contain rigid benzene rings, and they are all semi crystalline polymeric materials. Therefore, the flexural resilience is related to the crystallization, orientation, and conformation of the macromolecular chains in their aggregate structure. Due to the fact that there are only two methylene groups between the two benzene rings in the PET macromolecular chain, and the flexibility of the macromolecular chain is relatively poor, the PET macromolecular chain will not undergo a crystal transition under stress conditions. Moreover, crystalline PET macromolecules are linked to a nearly fully extended planar serrated conformation, and the macromolecular chain in the crystalline state has the most stable conformation.

Jakeways and others believe that the length of the C-axis of the unit lattice of PET stretching fibers reaches about 98% of the maximum stretching conformation length of the repeating unit. As long as they are slightly stretched (such as about 6%), they can become fully stretched fibers. Therefore, PET fibers have a higher resilience only when subjected to bending elastic recovery with a lower elongation. PBT fibers are different. Although the macromolecular chains are also in a planar zigzag conformation in the lattice, due to the inclusion of four methylene groups in the repeating unit of the macromolecular chain, the flexibility of the macromolecular chain is significantly higher than that of PET, so the bending and tensile resilience properties are better than those of PET fibers. However, PBT has α and β 2 different crystal forms. Under the action of external stress, the methylene segments in the macromolecular chain undergo a crystal transformation of both crystal forms, which is reversible. In the crystal form of PBT primary fibers, the unit lattice length is 86% of the maximum tensile conformation length of the repeating unit, α when the crystal form is stretched by 6%, it can occur β reversible transformation of crystal form and complete elongation of 12% α Crystal form: The unit lattice length of the mouth crystal form in PBT primary fibers reaches 98% of the maximum tensile conformation length of the repeating unit, 14,51. Therefore, PBT fibers can undergo reversible crystal form transformation at low elongation.

Therefore, PBT fibers can fully recover elastically at low elongation, with a higher flexural resilience than PT and PET fibers; The tensile resilience of PET fibers at low elongation is significantly higher than that of PET fibers. It is equivalent to PTT fiber, but its tensile resilience at high elongation is lower than that of PTT fiber. There are two methylene groups in the PET macromolecular chain between the terephthalic acid units. The macromolecular chain is arranged in a helical conformation in the lattice, and has a low energy "T G G Qing" conformation, that is, an obvious "Z" shaped conformation. This structure allows the PBT macromolecular chain to have the elasticity of deformation like a spring, giving the PBT fiber good internal resilience, thereby enabling it to have excellent elastic resilience, especially at high elongation, the tensile rebound rate is significantly higher than that of PET and PBT fibers.

Conclusion

a. Under the condition of deformation time of 20 min, the bending resilience of PBT fiber is the highest, followed by PTT fiber and PET fiber, and the bending resilience of all three fibers increases with the extension of recovery time. During measurement, a response time of 10 minutes can meet the requirements.

b. There is a significant correlation between fiber bending resilience and specific work at break. With the increase of the methylene number in the fiber, the specific work at break decreases, while the bending resilience increases. In addition, there is also an inverse relationship between the fiber tensile resilience and its Young's modulus. With the increase of the methylene number in the fiber, the fiber tensile resilience first increases, and then decreases with the increase of the methylene number, while the Young's modulus first decreases with the increase of the methylene number, and then decreases with the increase of the methylene number increase and slightly improve.

c. Fiber bending elastic recovery is a recovery at low elongation. The fiber bending elastic recovery performance is related to the crystal and orientation structure in the aggregate structure, as well as the conformation of macromolecular chains in the crystal structure.